1. Finished installation:

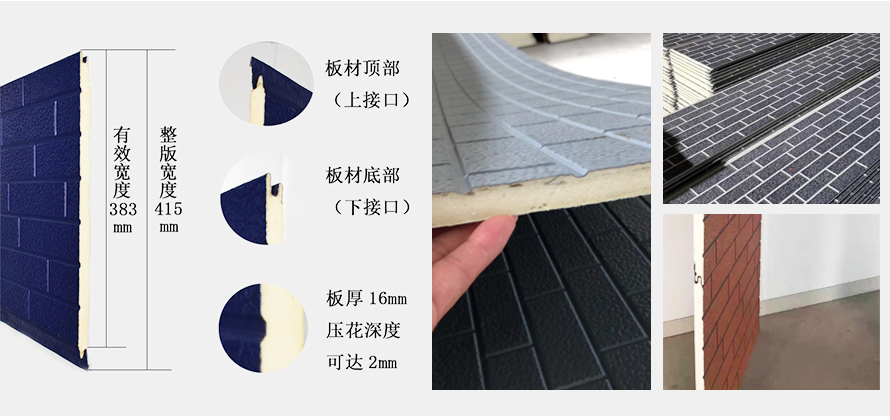

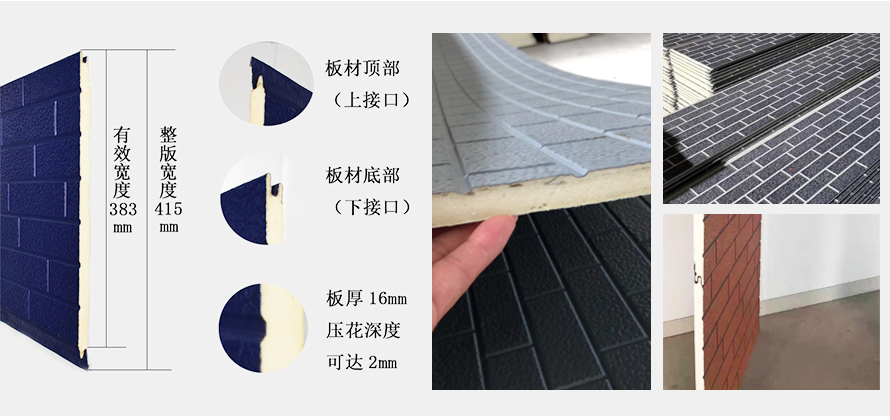

Finished materials, minimize on-site processing, easier and faster installation, can effectively reduce installation costs, speed up construction progress, and shorten the construction period;

Effectively eliminate the uncertainty caused by the working environment and workers, ensure excellent quality and stability; overcome the decorative quality problems caused by traditional materials due to accessories, workers' operations, grassroots and other reasons: such as paint cracking, tile falling off and so on.

2, weather resistance durability:

The metal decorative insulation board topcoat adopts high weathering polyester paint or fluorocarbon paint, and is coated on the base alloy steel plate by the baking paint process, and the surface layer forms a dense quaternary crystal layer, which effectively avoids cracking and falling off of the ordinary coating;

3. Wide adaptability:

The construction of metal decorative insulation board adopts keel hanging, which has low requirements on the flatness and cleanliness of the base layer; the plug-in installation between the board and the board, the joint seam, the yin and yang corners have corresponding fittings, and the glue is sealed and the joint is basically eliminated. It has low requirements on temperature and humidity of operation; it has strong adaptability to various building structures such as brick-concrete, frame, shear wall and steel structure.

4. Excellent environmental performance:

Finished materials and dry hanging construction of metal decorative insulation board greatly reduce the use of auxiliary materials (such as mortar) on site construction, effectively avoid dust on the construction site, and stack the materials in an orderly manner to ensure a clean construction environment.