Basic performance of metal engraved panels

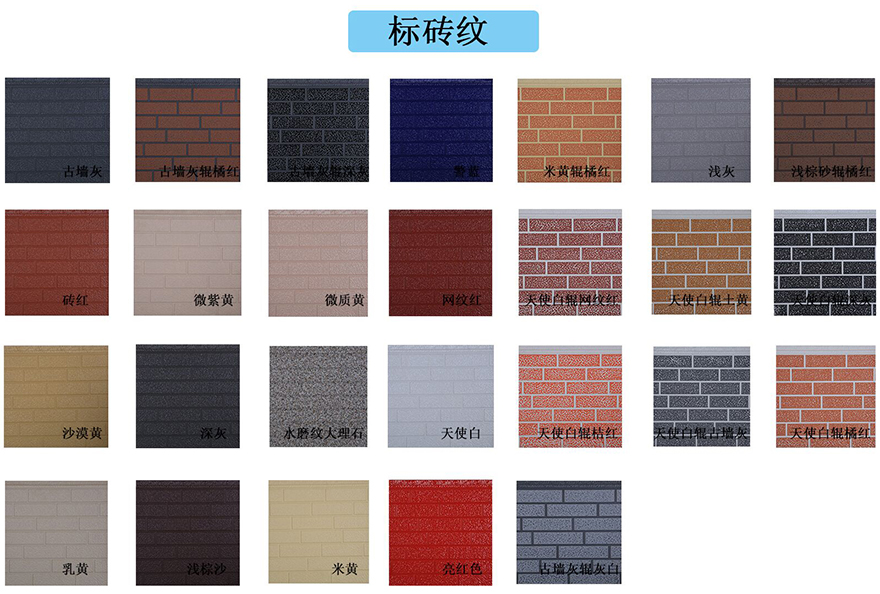

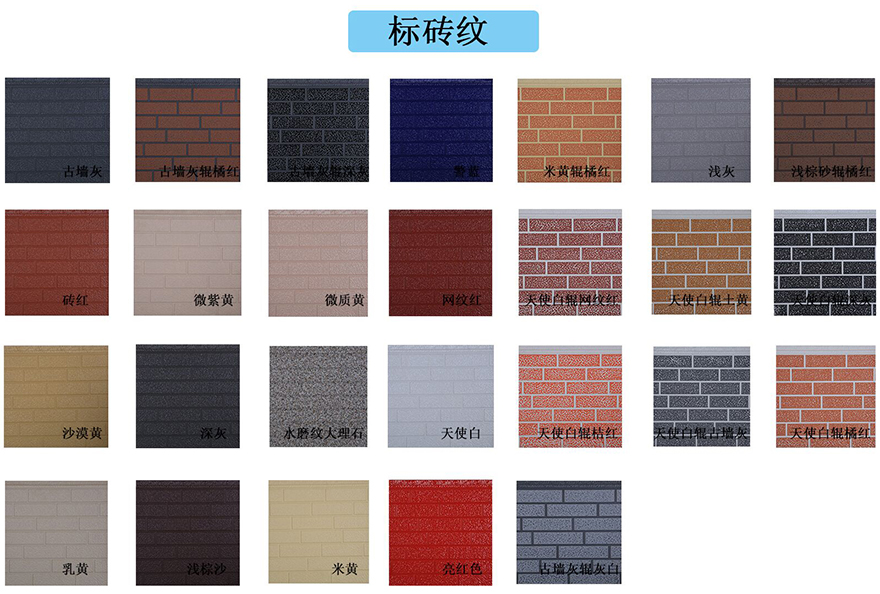

1. The metal plate substrate on the outer layer of the metal engraved plate is painted with aluminum alloy plate, color coated aluminum-zinc plate, color-coated aluminum-zinc alloy plate, stainless steel plate and copper plate, etc., and is rolled into various kinds by using specific equipment. Patterns that conform to the different styles of the architectural design or the owner's requirements, or are painted twice in various colors to form patterns such as imitation wood grain, stacked stone, fine stone, gravel, block, brick wall, etc. Architectural styling and color appearance requirements, to achieve a certain artistic effect

2. Insulation insulation materials are made of polystyrene foam (XPS, EPS), phenolic resin foam, honeycomb paper, honeycomb aluminum, rock wool and glass wool insulation materials, but also composite gypsum board and other sound insulation materials.

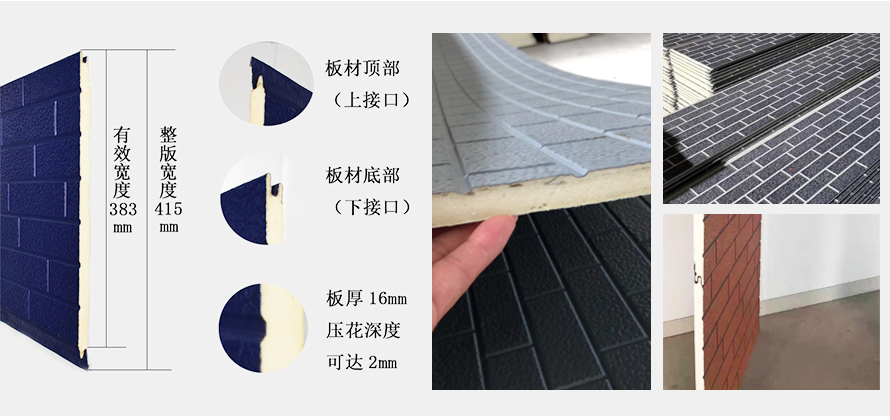

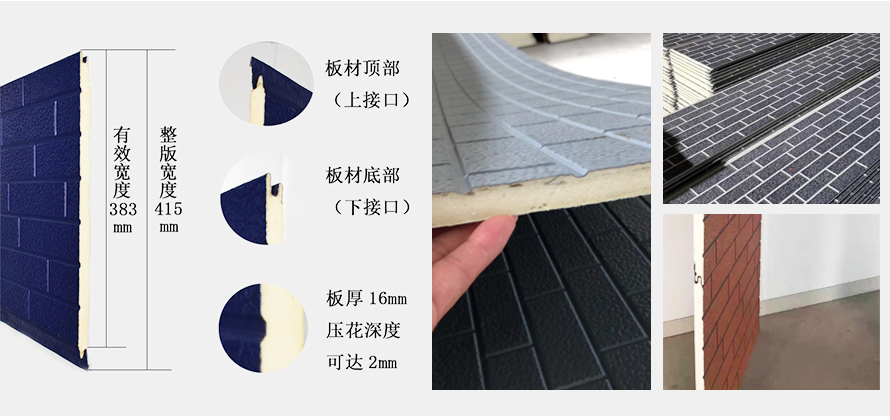

3. The board and the board have a good connection between the board and the main structure, and provide a complete set of connecting parts and fittings, which not only meet the installation strength requirements, but also avoid the generation of cold (heat) bridges, and the sheet resistance after embossing The folding ability and the resistance to thermal expansion and contraction are improved.

4. Absorbing many advantages of modern wall at home and abroad, it is suitable for civil and industrial buildings, including heat preservation, heat insulation, environmental protection, light weight, weather resistance, rainproof, antifreeze, sound insulation, earthquake resistance, ventilation, decoration, etc. The prefabricated plate with functions is integrated and has good structure and connection. The metal engraved plate has no cold (heat) bridge and no leakage, which effectively avoids the phenomenon of falling off and cracking. At the same time, it has various textures, simple construction and no season. The restrictions, dry hanging and other characteristics.