Metal inner wall embossed plate decorative package column construction method

1, the practice of the skeleton

The skeleton has two kinds of wood structure and steel structure. The skeleton of the wooden structure is made of square wood and is mainly used for affixing various colored metal inner wall embossing plates. Now take the concrete square column as an example, simply talk about the skeleton: firstly, the vertical skeleton is positioned by the embedded part, the connection between the horizontal and vertical frames, and the support of the skeleton and the cylinder are fixed. determine.

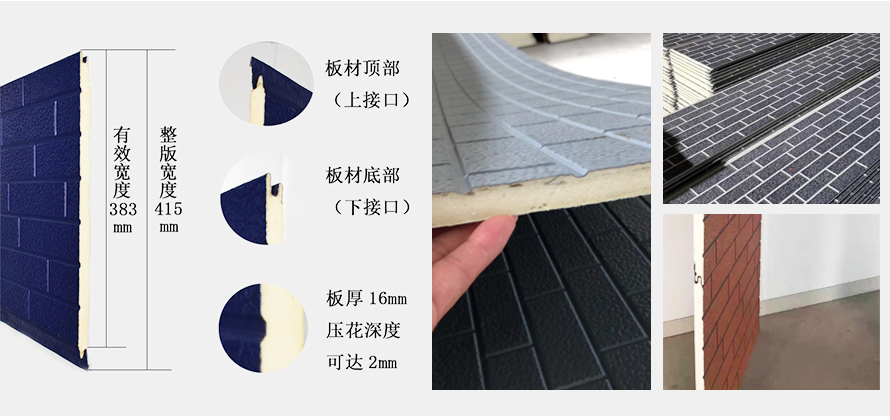

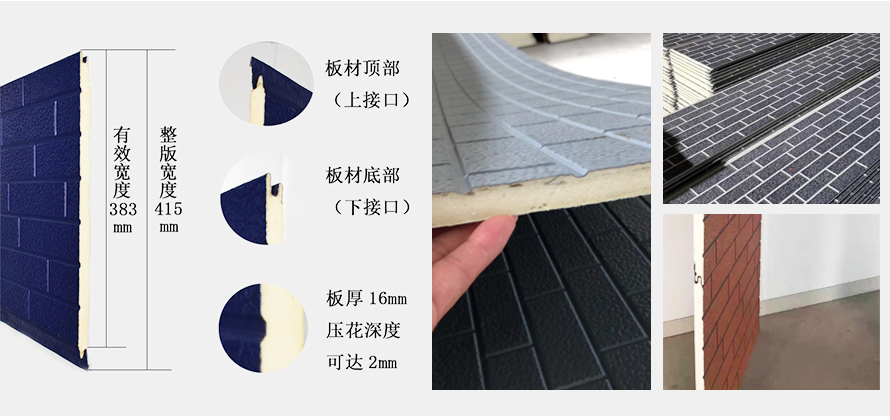

2. Fixation of the base board

The role of the base plate is to increase the rigidity of the column frame and facilitate the laying of the decorative panel. It is generally made of plywood, wood board or MDF, and the base board is directly fixed to the frame with nails or screws. The base plate must have a smooth surface and a high degree of accuracy to ensure the quality of the installation of the colored metal inner wall embossed plate, which is more demanding for the case of the packaged cylinder.

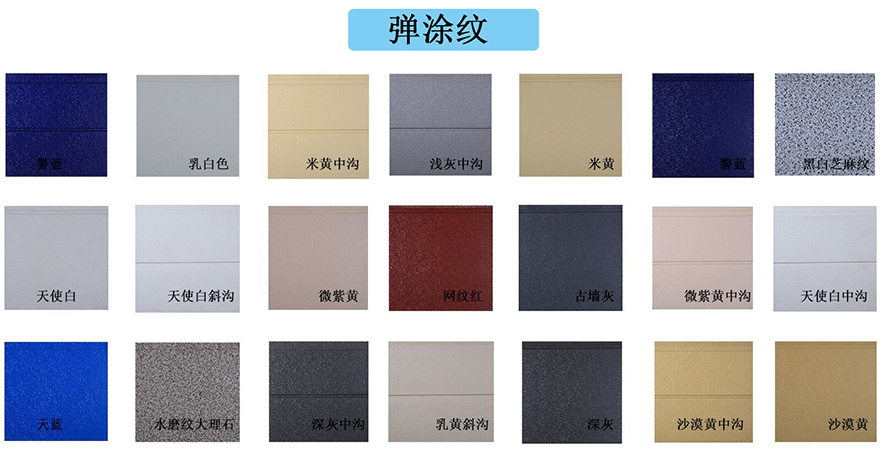

3. Installation of colored metal inner wall embossing plate

In the installation and fixing of the colored metal inner wall embossing plate, it is usually glued and nailed. It is not suitable for welding, because the high temperature of the welding will damage the colored film on the surface and ultimately affect the appearance; especially It is a colored metal inner wall embossed board with a mirror surface. If it is a single color, the welding will leave an indelible stain, which will lose the overall decorative effect; therefore, the decorative application welding method using this material is compared. Less. The gluing method is easy to operate and has the widest application. The nailing method is easy and secure to install, but the decorative surface is also affected. Regardless of the type of installation, it is necessary to cut the sheet accurately.