Metal carving heat insulation integrated board correct construction method

1. Bottom wall treatment: When the outer wall metal carving heat insulation integrated board is used, the release agent, concrete residue, lime soil and other debris on the base wall should be cleaned to ensure the infiltration and penetration of the bonding mortar and the bottom layer. The bond strength of the mortar.

2, the layout of the line: according to the vertical angle of the building to hang the vertical line or use the theodolite to release the straight line, as the baseline, control the vertical angle of the vertical angle, pop up the vertical line and the horizontal line from the bottom to the top, To control the straightness and levelness of the exterior wall metal carved insulation board.

3. Mixing special binder: The slurry is mixed with a hand-held electric mixer for about 5 minutes until the consistency is moderate. Ensure that the polymer mortar reaches the strength of the bond.

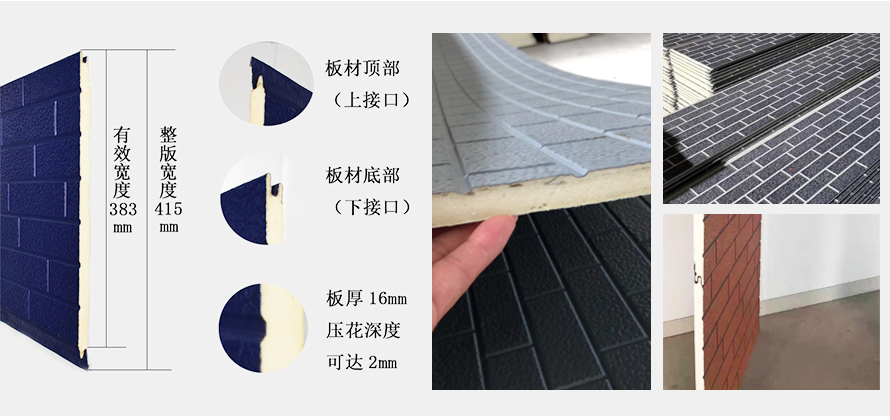

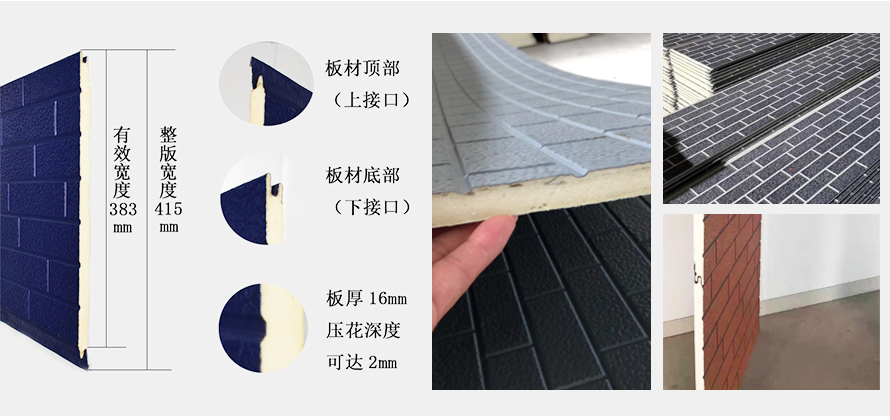

4. Applying bonding mortar: When using the external wall metal carving insulation board, the point frame method is adopted. It is 80-100MM wide and 10-30MM thick bonding mortar on the periphery of the outer wall metal carving insulation board, and it is left in the periphery. 50 mm exhaust passage, then the center of the paste 100MM diameter, thickness 10-30MM bonding mortar cake, the distance is 100MM (according to the size of the board), and the total paved area of the bonded mortar is not less than a single The outer wall of the block is engraved with 40%-50% of the area of the board.

5, row board: arrange the device in horizontal order, the upper and lower should be straight, the yin and yang angle should be square.

6. Posting device: When posting, it should evenly knead the outer wall metal carving heat preservation integrated board, so that the bonding mortar and the wall surface are closely adhered, and it is flush with the adjacent outer wall metal carved heat preservation integrated board, and the bonded mortar is extruded. Use a blade to flatten it to ensure that the bond is tight. Use a 2 m ruler and a support plate to check the flatness and straightness. When sticking the plate, pay attention to remove the bonding mortar from the edge of the plate, so that the plate is between the plates. No "head ash.

7. Anchoring: After the external wall metal carved heat preservation integrated board is posted, according to the planning request, the mechanical anchor (expansion tube screw) should be used to fix the extruded board, and the impact drill should be used in the gap between the two plates of insulation and decoration. Punch the hole, the hole diameter depends on the diameter of the anchor (expansion tube screw), the length of the anchor (expansion tube screw) depends on the thickness of the outer wall metal carved insulation board and the depth of the wall must not be less than the planning request, anchor ( The expansion head screw) The nail head and the disc should be in the groove between the joints of the board, and must not exceed the surface of the metal wall of the outer wall of the metal-inserted insulation board, hidden in the metal-paneled insulation board of the outer wall, so that the metal wall of the outer wall is insulated and integrated. The decoration of the board will not be affected.

8. Sewing treatment: After cleaning the surface with a cleaning agent (determine whether to use masking tape according to the actual situation), immediately write the material such as grouting agent in the gap between the metal engraved and heat-insulating boards. The injection should be contacted. Plan the drawings to pay attention to the construction thickness of the grouting agent. There should be no gaps or air bubbles. The gray knives should move at a constant speed along the joints. The strength of the kneading joint should also be uniform.

9. Finishing of the board: Remove the board-covered paper and other debris within 3 days, and immediately clean the board surface.

10. Self-test: If you find a problem, repeat the above process.

11. Maintenance and inspection of products.