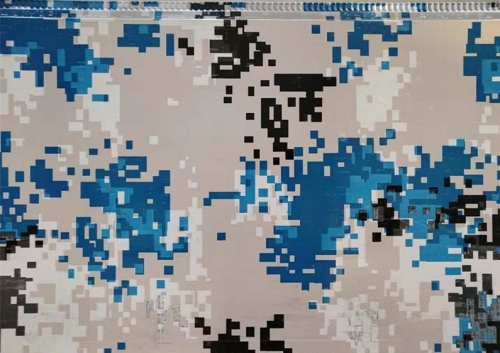

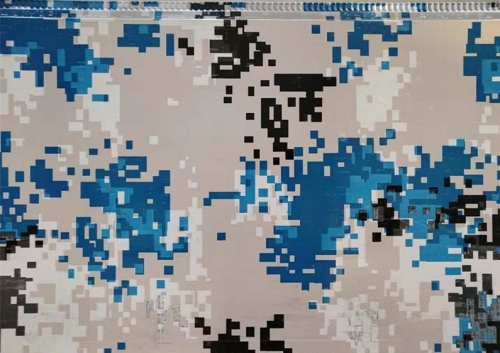

PMW-018-Air Force Camouflage

China's traditional metal-carved composite board materials, such as polyurethane and other insulation materials, are basically flammable materials, in the process of practice, basically unsuccessful. The basic function of the metal-engraved composite board is both fireproof and heat-insulating. After practice, aluminum silicate insulation material has been used to replace the traditional metal-engraved composite board material. Features of ceramic fiber metal carved composite board products:

1. High compressive strength and long service life

2, easy to cut, easy to install, not easy to break

3, good resistance to wind erosion

4, uniform fiber distribution, stable performance

5, the surface is flat, accurate size

6. Uniform structure and good integrity. Specific preparation method: take aluminum silicate fiber, add inorganic binder, organic binder and additive, and fully stir and mix pulp. Then use mechanical extrusion or manual molding. The blank is discharged, and after 100-150 ° C drying treatment, the bonding agent inside the product is gelled and hardened to achieve the required hardness. The dried product is cut, ground, and drilled using mechanical equipment for further deep processing.

Compatibility of raw materials: The content of each component of this product is 40-60 ceramic fiber, 20-30 inorganic binder, 0.5-1.5 organic binder and 20-30 additive.