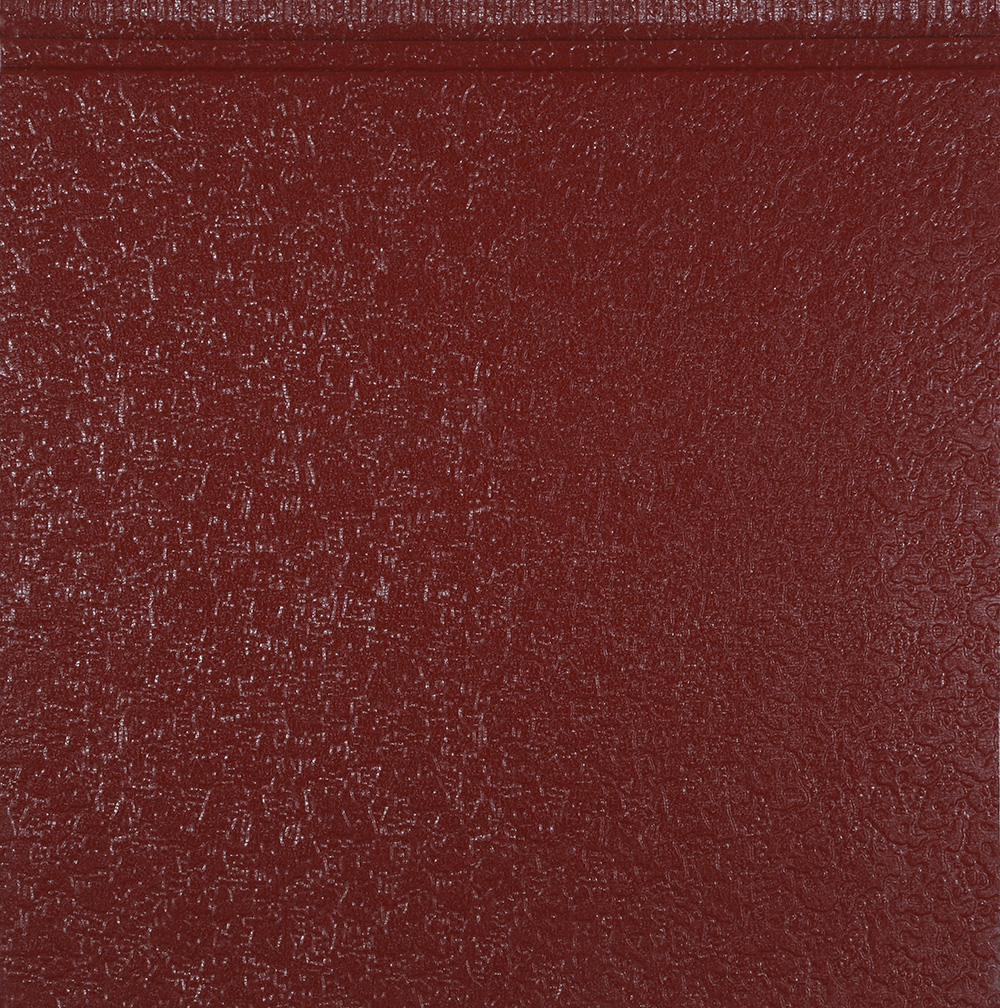

Elastic smear (mesh red)

External wall metal engraved board waterproof engineering construction method

First, construction preparation

(1) Raw materials:

1. Polystyrene board: ordinary type spontaneous polystyrene foam board;

2. Plastic plate: PVC soft plastic plate, thickness 1.5~2.0MM;

3. Plastic pipe: PVC plastic pipe;

4. Asphalt linoleum: construction petroleum asphalt (30 A or 30 B), No. 350 petroleum asphalt linoleum;

5. Cement: 325 ordinary cement or slag cement;

6. Sand: medium sand content ≯ 3%;

(2) Preparation for processing the exterior wall panel materials of the villa:

1. Insulation waterproof strip: The polystyrene board is cut into 20MM thick, and the 150 mm wide strip is bonded with the linoleum strip;

2. Plastic waterproof strip: According to the measured width of the outer wall board waterproof groove plus 25MM.

Second, the operation process

1. Firstly, according to the drawings, the existing integral concrete water retaining platform should be made, and the outside should be used as the drainage slope;

2. Repair the damaged exterior wall panel. If the strength is not reached, the wall shall not be hoisted;

3. After the inner wall is supported, the outer wall panel is hoisted, and a waterproof and thermal insulation strip is inserted outside the side pillar, and the outer side of the keyway is blocked with the linoleum roll;

4. The concrete is poured into the side column, the keyway steel is welded and the concrete is poured, and the slurry leakage in the joint is cleaned in time;

5. Insert a plastic strip into the vertical seam;

6. If the flat seam is too wide, the water is damaged, and the draping is too large, the squeegee should be embedded in the seam;

7. Install a drain pipe in the cross seam;

8. Use mortar to sew seams and horizontal seams;

9. Water spray test.