Metal carving exterior wall decoration board supervision points

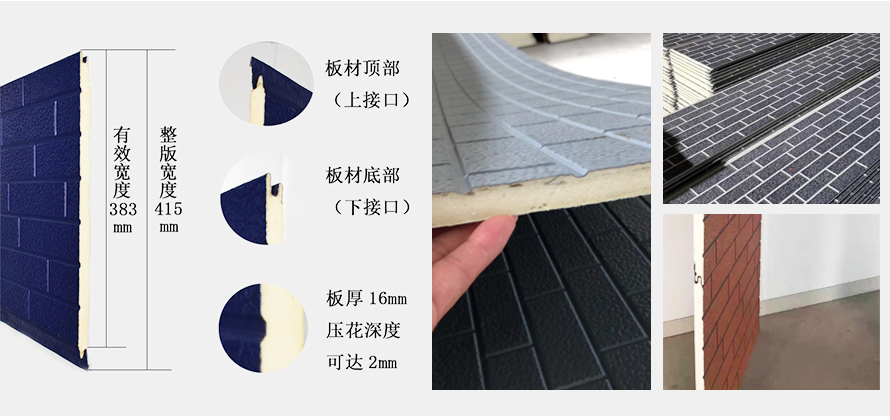

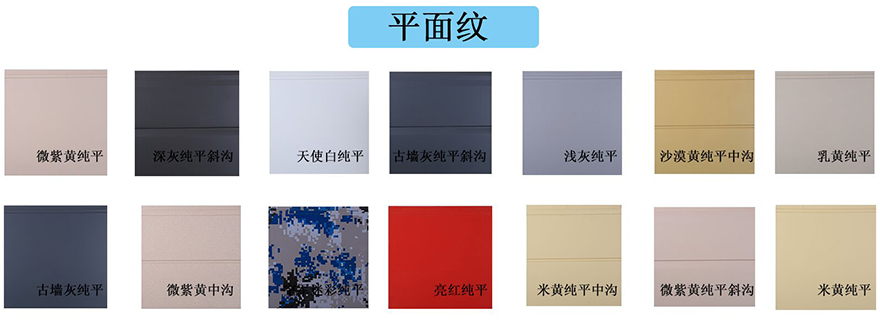

Metal-carved exterior wall decorative slab engineering expert building exterior wall building energy-saving system designed for thermal insulation decoration integration refers to EPS, XPS, polyurethane, phenolic foam or inorganic foaming materials and other insulation materials with a variety of shapes, multiple colors Metal decorative insulation board or inorganic pre-coated decorative board organic compound.

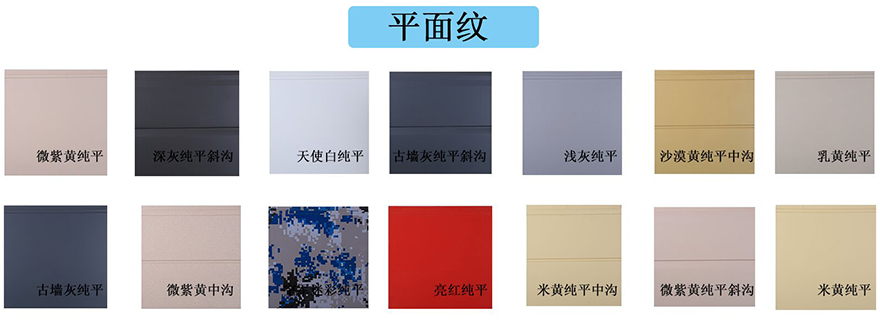

Insulation and decoration integrated system is generally applied to high-rise public construction projects, so the system coating requires long-life, weather-resistant and stain-resistant coating products. We generally advocate the use of fluorocarbon coatings.

In the specific application process, although they have obvious functional advantages compared with the traditional wet operation insulation system, there are also many problems and difficulties in marketing and construction applications.

1. Supervising personnel monitor the construction conditions against the supervisors

1. The base wall should meet the requirements of the acceptance specification, and the construction party should use 1:3 cement mortar to level.

2. The ambient temperature during construction should not be lower than 5 °C, and the wind should not be greater than 5, and should not be applied in rainy days without protective measures.

Second, the supervision points

1. The thermal insulation decorative board paste project should re-examine the following materials and their performance indexes: the setting time, installation and compressive strength of the cement for bonding; the water absorption, frost resistance and impact resistance of the insulation board;

2, insulation decorative board paste project should be accepted for the following concealed items: the base layer treatment; the bond point of the board and the base layer and the bonded area;

3. Before the heat preservation decorative board is pasted and during the construction process, the sample parts should be made on the same base layer, and the bonding strength of the sample board insulation board should be tested.

4. The base wall, insulation board, cement and adhesive for bonding, and caulking materials shall meet the design requirements and relevant current standards.

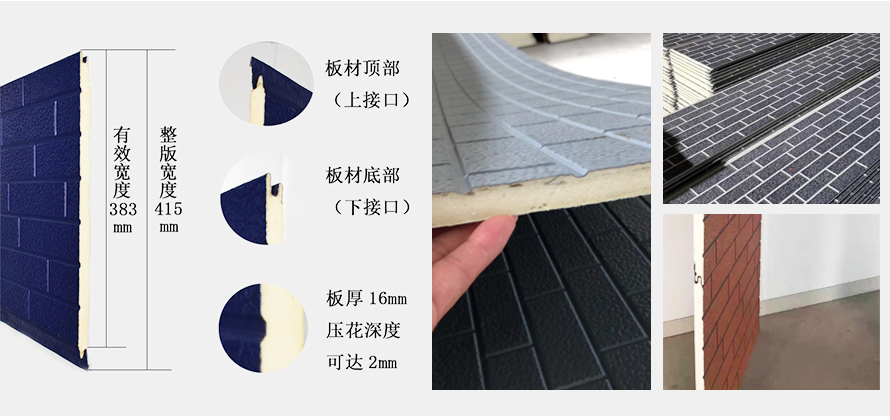

5. The arrangement and bonding area of the thermal insulation decorative board and the base layer should meet the requirements of this standard.

6. The variety, specifications and arrangement of thermal insulation decorative panels should meet the design requirements. Insulation board bonding must be reliable